產品情報 »

產品目錄

» 協作機械手臂用 真空夾取單元

» Vacuum Grippers (Ejector Type)

產品目錄

產品一覽

- 壓縮空氣管理系統

- 方向控制元件

- 氣壓缸

- 旋轉缸/氣壓夾爪

- 電動驅動器/單軸機器人

- 真空設備(真空發生器/真空吸盤/其他)

- 協作機械手臂用 真空夾取單元

- Compact Compressor

- 壓縮空氣清淨化元件

- 模組型F.R.L./壓力控制元件

- 模組型F.R.L

- 壓力控制元件

- 增壓缸

- 潤滑元件

- 接頭&氣壓管

- 流量控制元件

- 消音器/油霧回收器/空氣噴槍/壓力錶

- 開關/感測器/控制器

- 靜電消除器

-

產業用通訊元件/無線系統

- Wireless System: PROFINET Compatible Products

- Wireless System: EtherNet/IP Compatible Products

- Wireless System: EtherCAT Compatible Products

- Wireless System: IO-Link Compatible Products

- Wireless System: CC-Link Compatible

- Wireless System: DeviceNet Compatible Products

- Industrial Device Communication Equipment: PROFINET Compatible Products

- Industrial Device Communication Equipment: EtherNet/IP Compatible Products

- Industrial Device Communication Equipment: EtherCAT Compatible Products

- Industrial Device Communication Equipment: Modbus TCP Compatible Products

- Industrial Device Communication Equipment: ETHERNET POWERLINK Compatible Products

- Industrial Device Communication Equipment: CC-Link IE Field Compatible Products

- Industrial Device Communication Equipment: SSCNET III Compatible Products

- Industrial Device Communication Equipment: MECHATROLINK-Ⅲ Compatible Products

- Industrial Device Communication Equipment: PROFIsafe Compatible Products

- Industrial Device Communication Equipment: IO-Link Compatible Products

- Industrial Device Communication Equipment: PROFIBUS Compatible Products

- Industrial Device Communication Equipment: DeviceNet Compatible Products

- Industrial Device Communication Equipment: CC-Link Compatible Products

- Industrial Device Communication Equipment: AS-interface Compatible Products

- Industrial Device Communication Equipment: CANopen Compatible Products

- Industrial Device Communication Equipment: CompoNet Compatible Products

- Industrial Device Communication Equipment: Interbus Compatible Products

- Industrial Device Communication Equipment: MECHATROLINK-Ⅱ Compatible Products

- Other: RS232C Compatible Products

- Other: RS485 Compatible Products

- Wireless System: PROFINET Compatible Products

- 流體閥

- 藥液用閥/接頭&針閥/配管

- 製程幫浦(膜片式幫浦)

- 恆溫元件

- 製程氣體用元件

- 高真空元件

- 工業用過濾器/燒結金屬濾芯

- 計裝用補助元件

- 油壓元件

按主題/行業分類的目錄

Vacuum Grippers (Ejector Type)

Vacuum Gripper System (Foam Type) ZGS

-

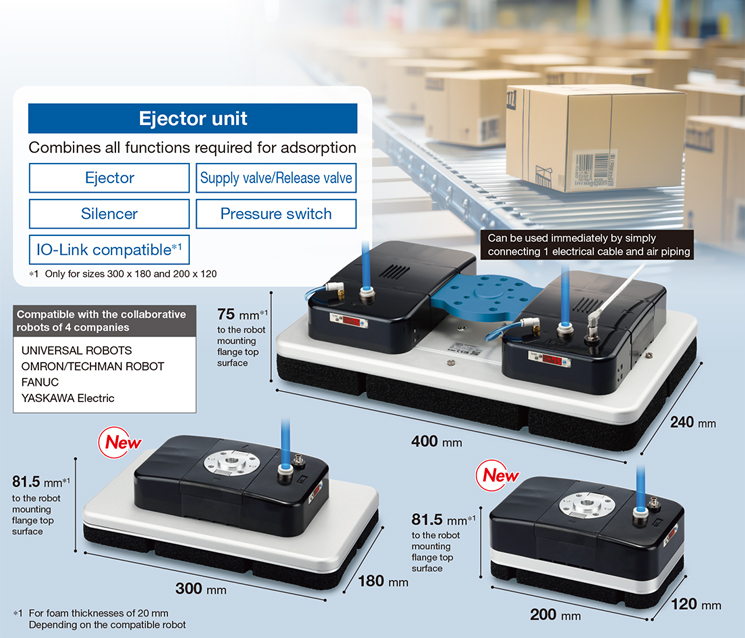

・Compatible with the collaborative robots of 4 companies

UNIVERSAL ROBOTS OMRON/TECHMAN ROBOT,FANUC, YASKAWA Electric

[New]

・Suitable for the palletizing and depalletizing of corrugated cardboard,

etc.

・Ejector unit

Combines all functions required for adsorption

(Ejector, Supply valve/Release valve, Silencer, Pressure switch)

・Can be used immediately by simply connecting 1 electrical cable and air

piping

・Weight: 3.9 kg∗ Reduces the load on robots

∗ For ZGSNPK-400240BS4-RM1C8

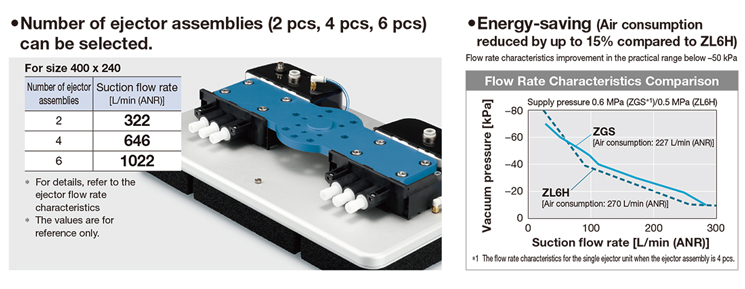

・CO2 emissions (Air consumption): Max. 15% reduction (SMC comparison)

Ejector with new design

227 L/min (ANR) ← 270 L/min (ANR)

Compared to ZL6H (Supply pressure: 0.6 MPa)

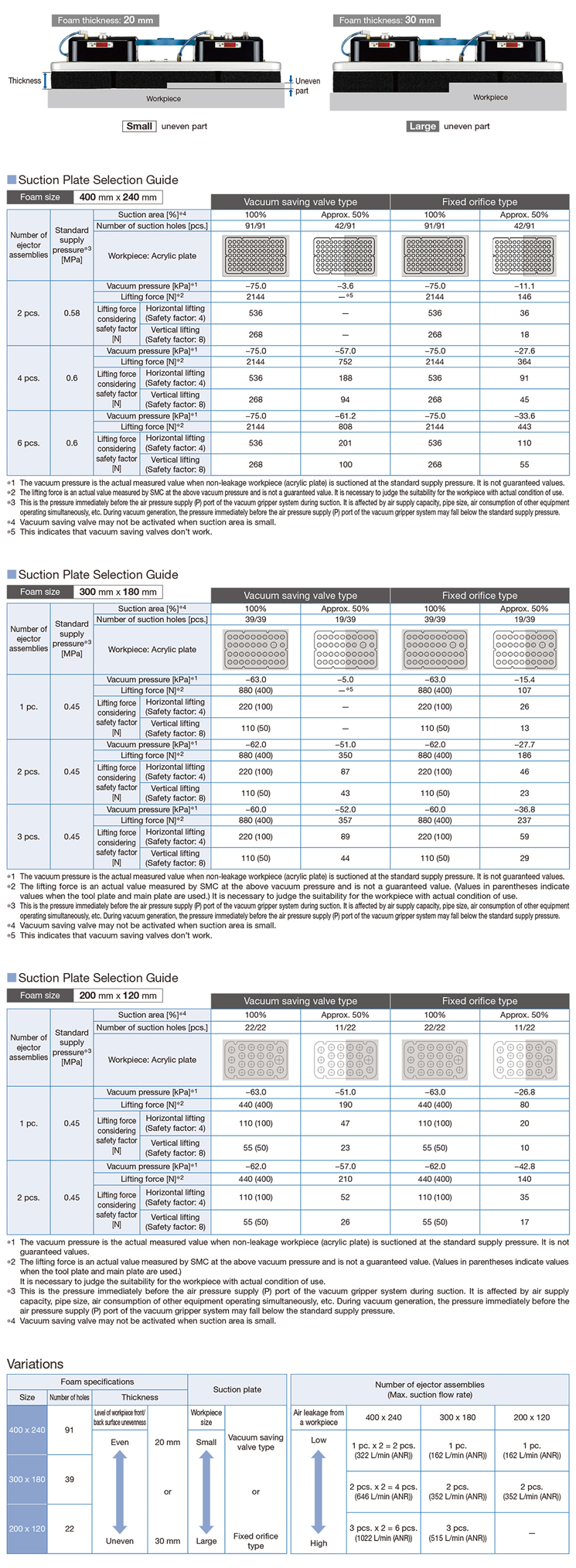

| Series | Cup form | Foam specifications Size | Foam specifications Number of holes | Foam specifications Thickness | Theoretical lifting force [N] |

|---|---|---|---|---|---|

| ZGS | Foam | 400mm×240mm | 91 | 20mm 30mm | 2144 |

產品特點

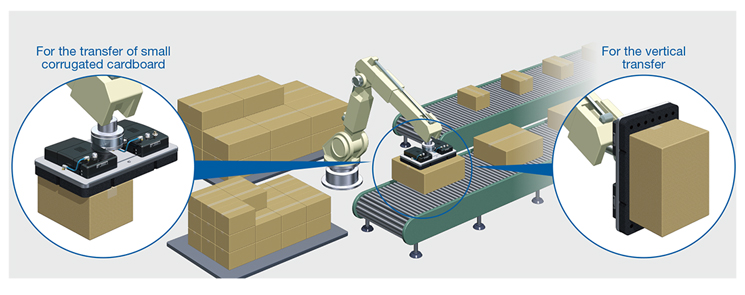

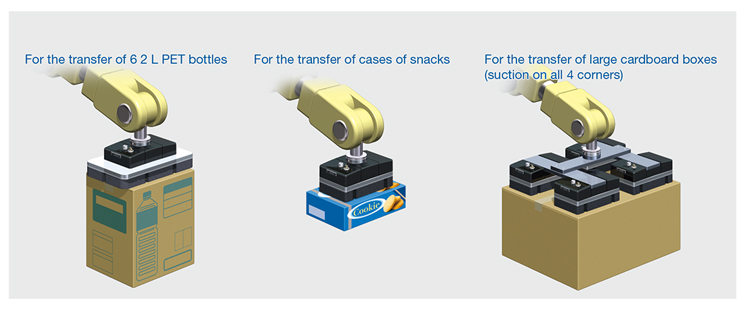

Suitable for the palletizing and depalletizing of corrugated cardboard, etc.

Foam size: 300 mm x 180 mm / 200 mm x 120 mm New

Weight:

1.3 kg ( 200 × 120 )

1.8 kg ( 300 × 180 )

3.9 kg ( 400 × 240 )

CO2 emissions (Air consumption): Max. 15% reduction (SMC comparison)

Ejector with new design

227 L/min (ANR) ← 270 L/min (ANR)

Compared to ZL6H (Supply pressure: 0.6 MPa)

Lifting force

440 N (200 x 120) (At −63 kPa)

880 N (300 x 180) (At −63 kPa)

2144 N (400 x 240) (At −75 kPa)

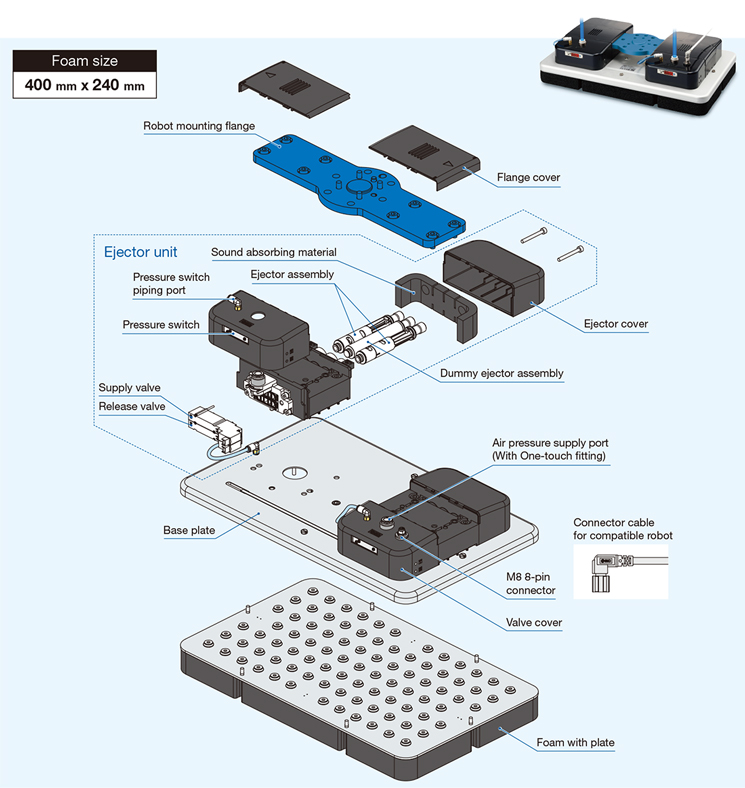

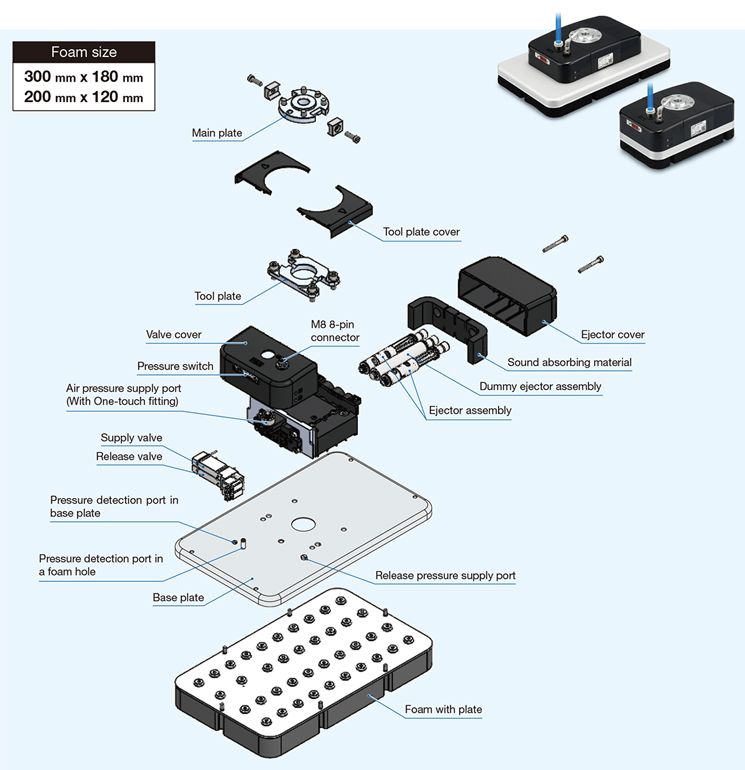

Construction Diagram

Application Examples

Construction Diagram

Application Examples

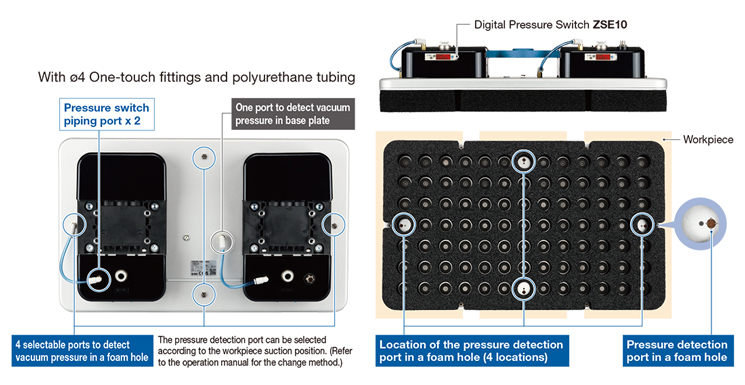

Ejector Unit

Newly designed ejector for the Vacuum Gripper System

Built-in pressure switch.

Pressure in a foam can be detected.

Selectable pressure detection ports (300 mm x 180 mm, 200 x 120 mm)

LED indicator for supply and release valve operation.

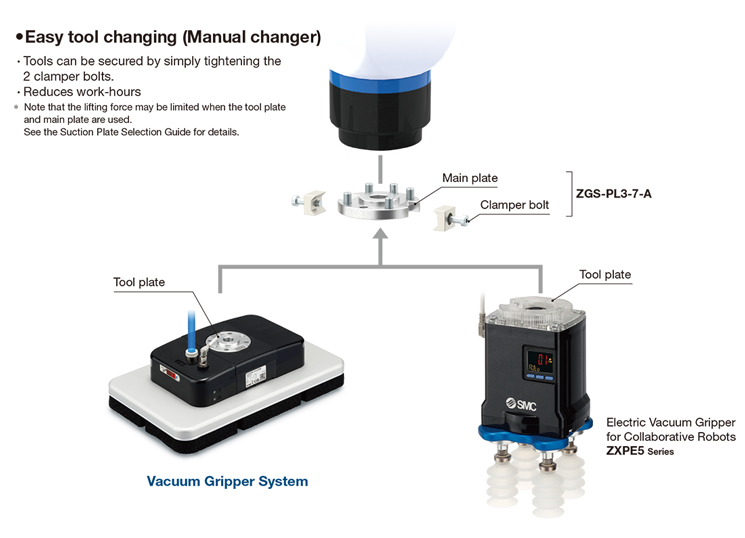

Easy tool changing due to common tool changer∗

∗ Only for sizes 300 x 180 and 200 x 120

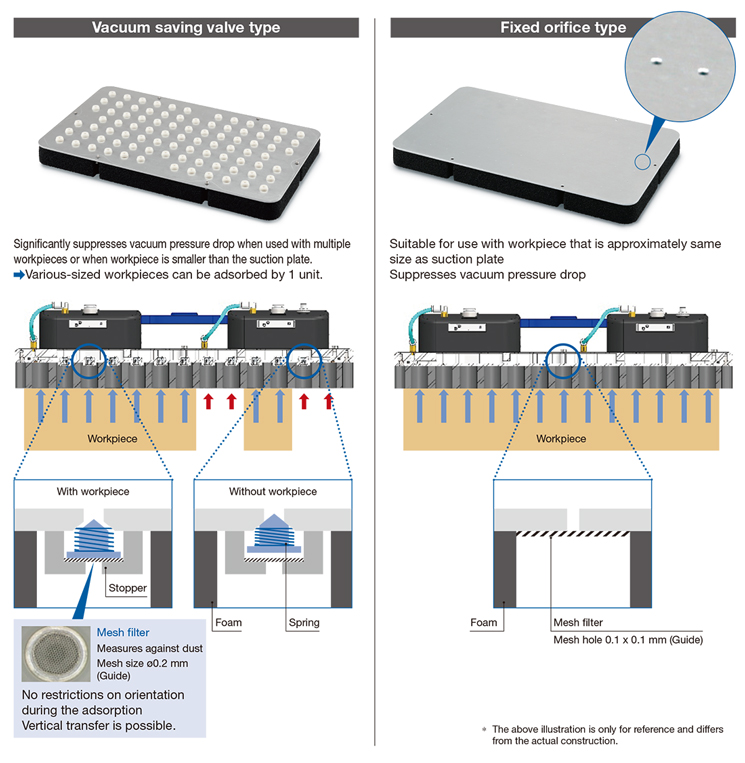

Suction Plate

2 suction plates can be selected according to the workpiece size.

2 foam thicknesses can be selected according to the workpiece surface shape.

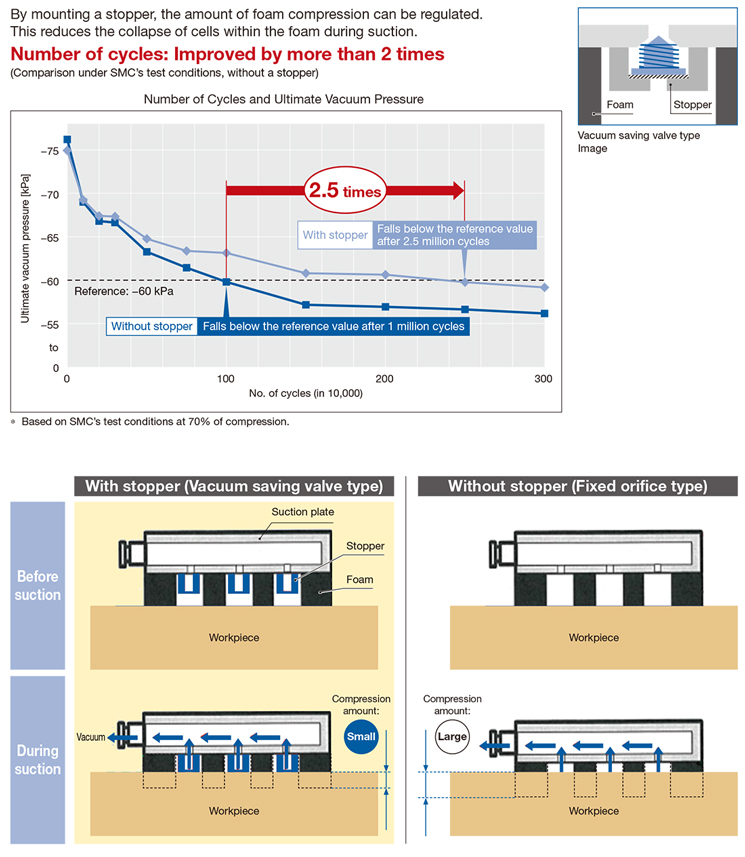

Improved foam durability due to stopper