Product Information »

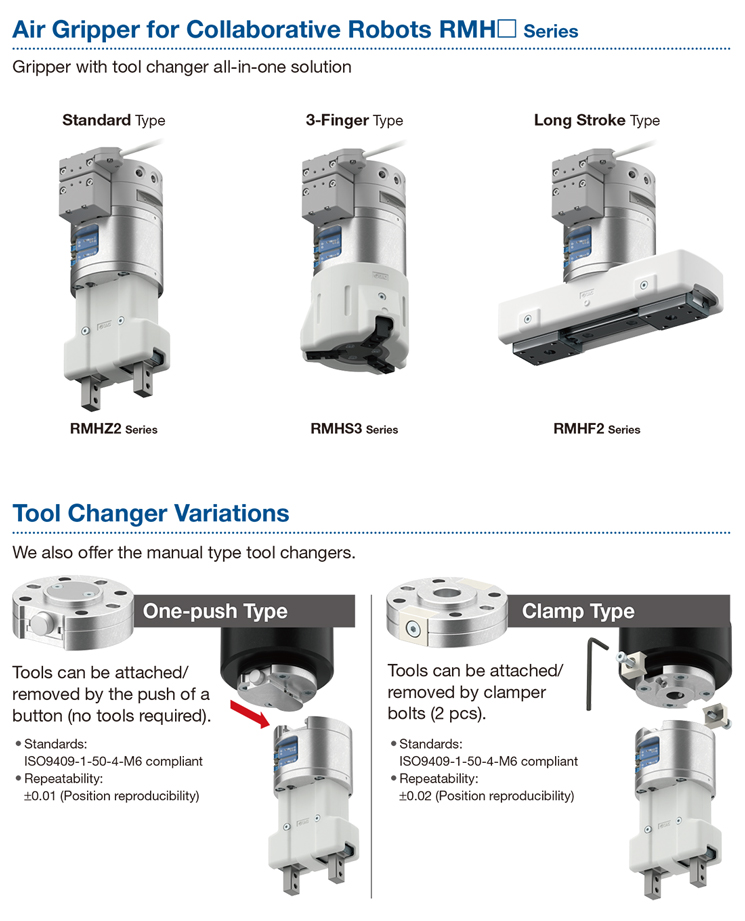

New Products:Tool Changer/Auto Type RMTA Series

New Product Information

Tool Changer/Auto Type RMTA Series

Updated Jan-25

- Robot hand tool automatic exchange

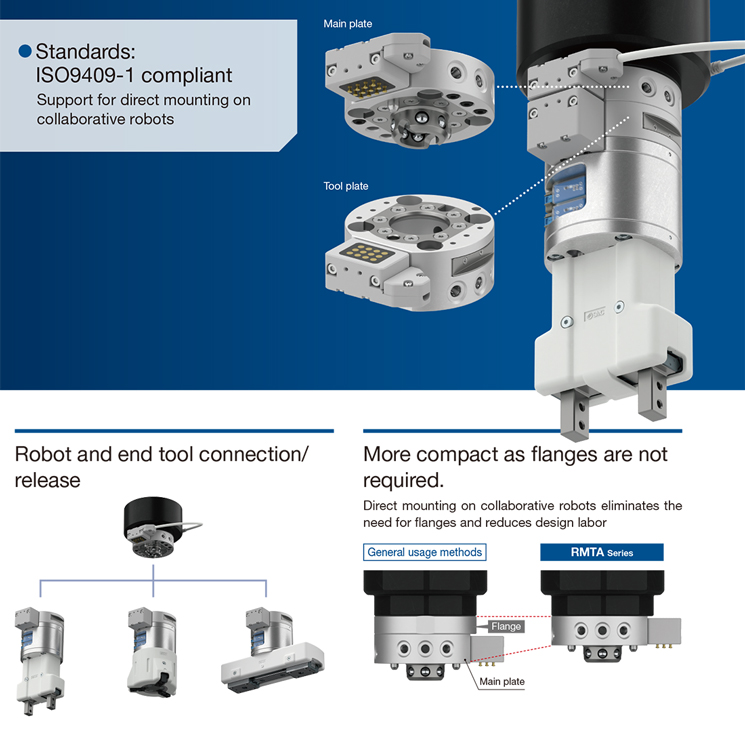

- Standards: ISO9409-1 compliant

Support for direct mounting on collaborative robots - Robot and end tool connection/release

- More compact as flanges are not required.

Direct mounting on collaborative robots eliminates the need for flanges and reduces design labor - Supports a work load of up to 20 kg (Work load: 5 kg, 10 kg, 20 kg)

Product Features

Robot hand tool automatic exchange

Work load: 5 kg, 10 kg, 20 kg

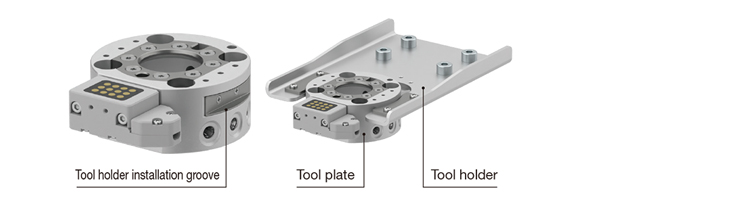

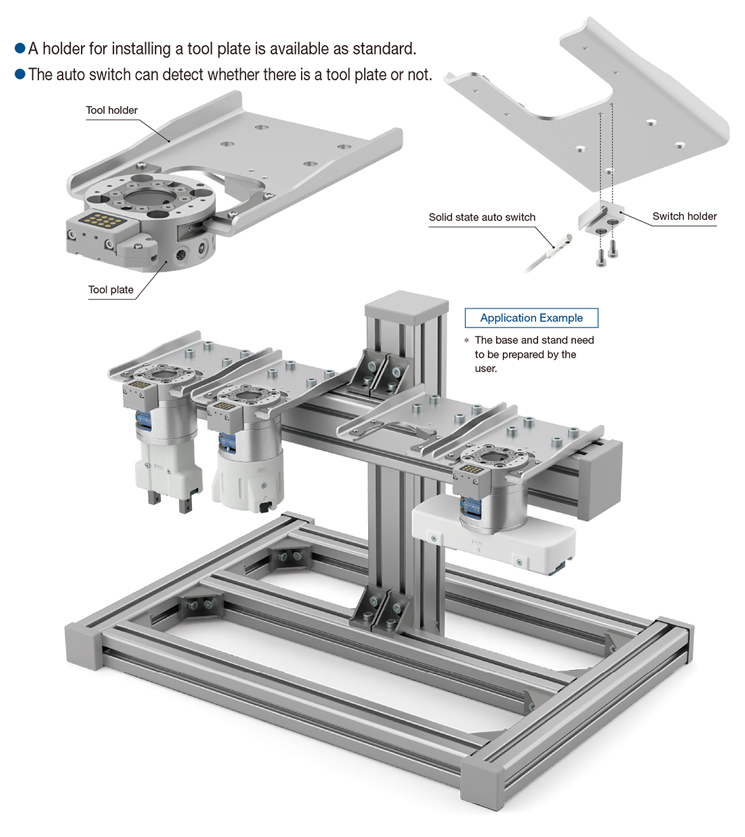

Integrating the mounting groove of the tool holder

Reducing the design labor required to install the tool plate

Select the method used to install the tool plate.

High precision and high rigidity

Repeatability: ±0.01 mm (Position reproducibility)

Allowable bending moment: 17.4 N·m (10 kg carrying capacity)

Supports a work load of up to 20 kg

Work load: 5 kg, 10 kg, 20 kg

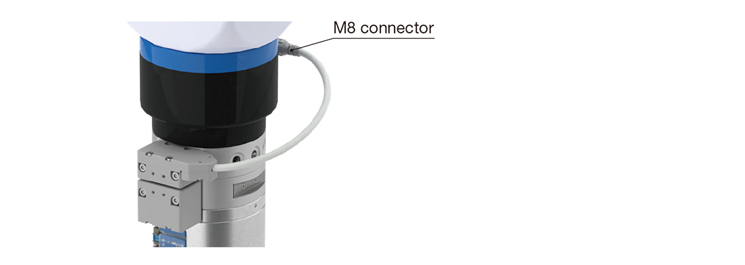

Direct mounting to the tool I/O is possible with an M8 connector.

∗ 10 kg type only

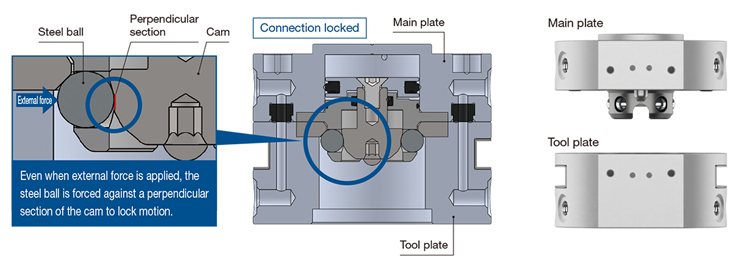

Drop prevention

Drop prevention mechanism locks the actuator so parts remain locked in place even if air pressure drops.

Uses a safety construction where the connection is not released even when an external force is applied

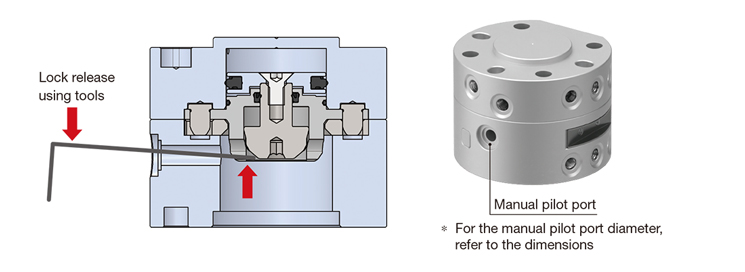

Manual pilot port

The plate can be released in the event of an air pressure drop by inserting a tool into the manual operation port.

Tool holder

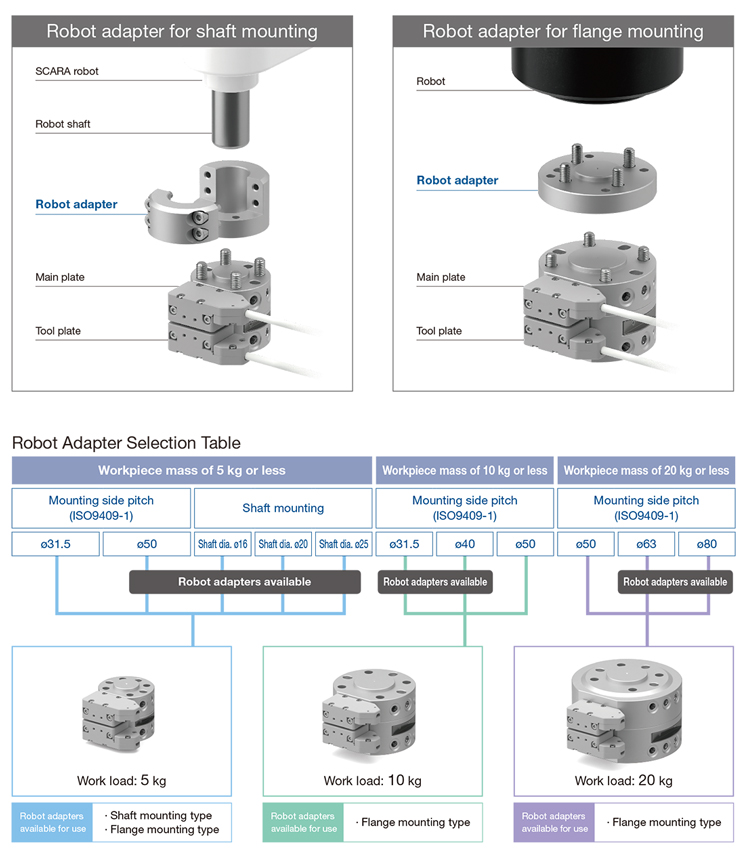

The robot adapter enables mounting to a wide range of robots.

Can also be used with the tool changer on shaft-mounted SCARA robots or robots with different flange mounting dimensions.

Related Products