New Product Information

Air Grippers for Collaborative Robots RMH□ Series

Updated Sep-23

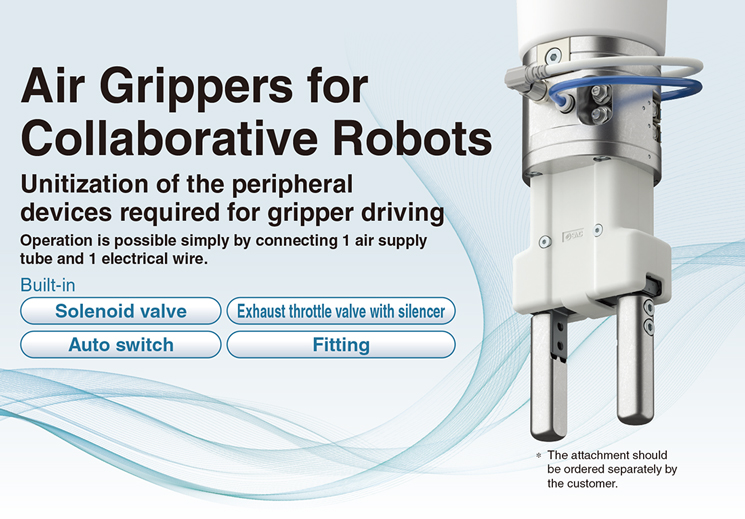

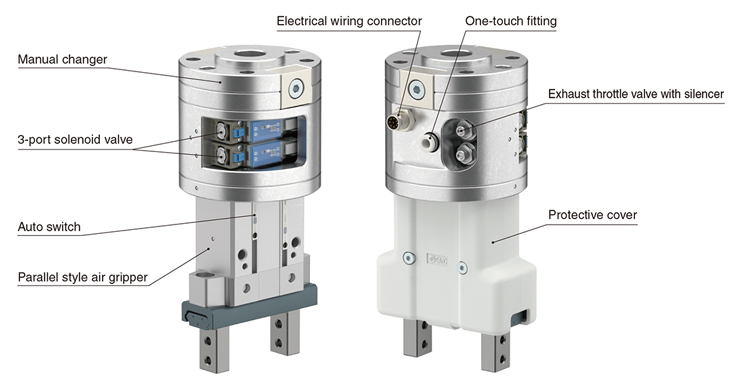

- Unitization of the peripheral devices required for gripper driving

Operation is possible simply by connecting 1 air supply tube and

1 electrical wire.

Built-in solenoid valve, exhaust throttle valve with silencer, auto switch, fitting, etc. - 3 types of grippers available for use with a variety of workpieces

- Can be used with the collaborative robots of 12 companies

- Manual changer built in as standard

Allows for easy tool changing and labor saving - Air consumption reduced by up to 80%

Product Features

Unitization of the peripheral devices required for gripper driving

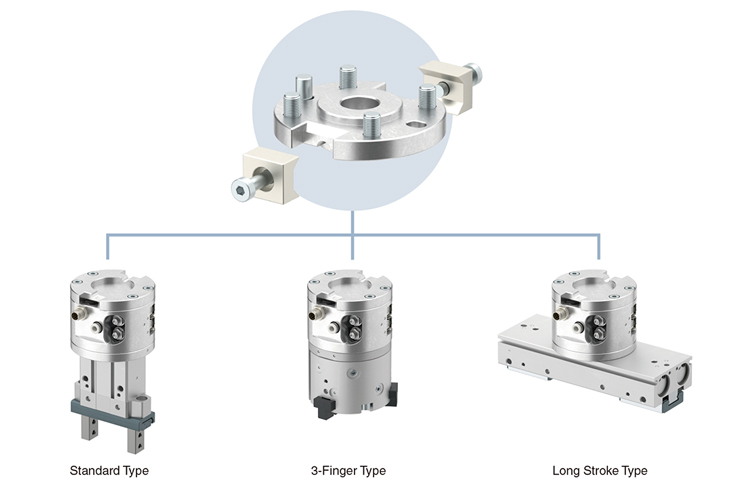

3 types of grippers available for use with a variety of workpieces

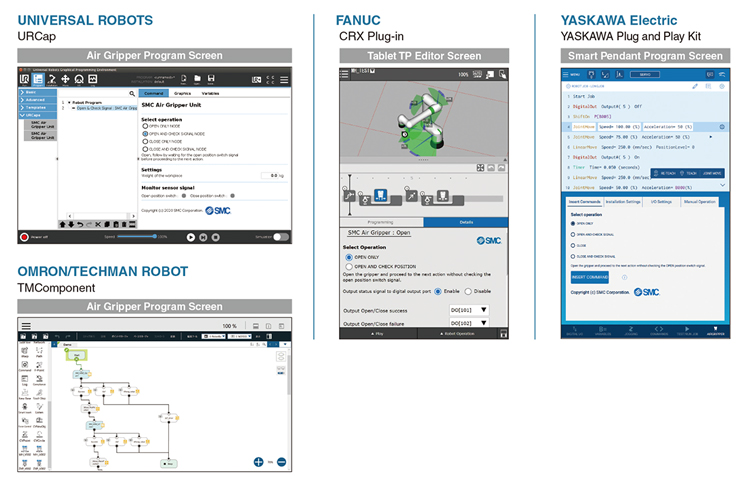

Can be used with the collaborative robots of 12 companies

UNIVERSAL ROBOTS, OMRON/TECHMAN ROBOT, FANUC, YASKAWA Electric, Mitsubishi Electric, HAN’S ROBOT, KUKA, DOOSAN ROBOTICS, SIASUN, JAKA, AUBO, ABBCan be used with the collaborative robots of 12 companies

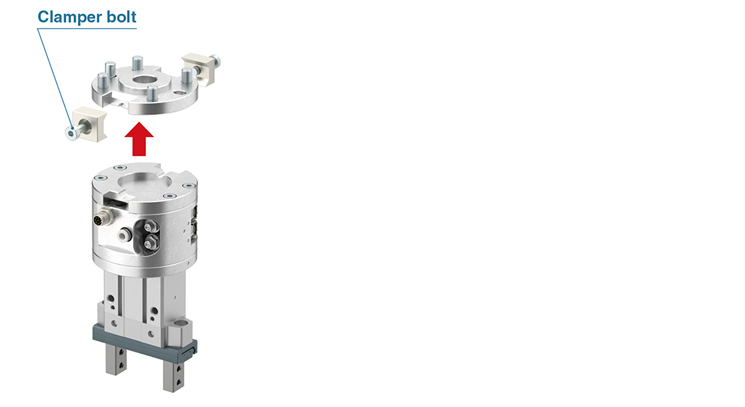

Manual changer built in as standard

・Allows for easy tool changing and labor saving

・Tools can be secured by simply tightening the 2 clamper bolts.Manual changer built in as standard

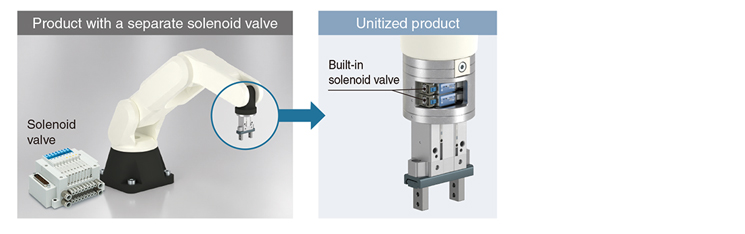

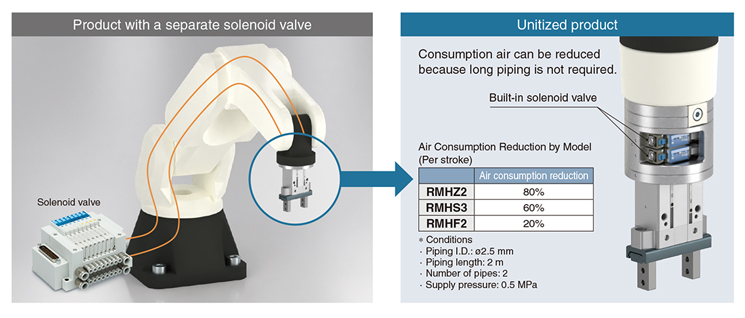

Air consumption reduced by up to 80%

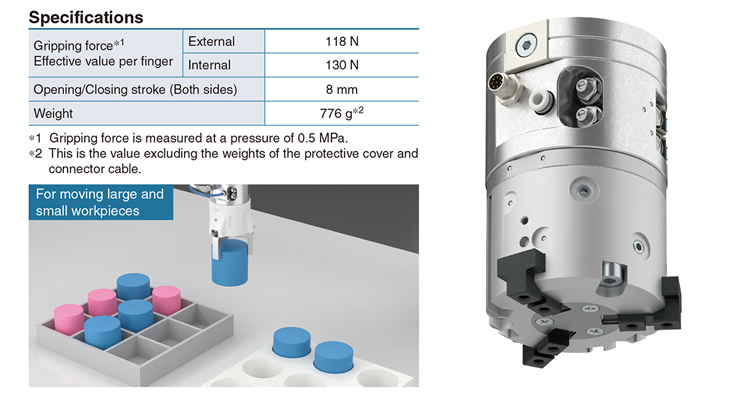

Standard Type RMHZ2 Series

・High rigidity and precision are achieved by integrating the guide and finger.

・With high-precision linear guideStandard Type RMHZ2 Series

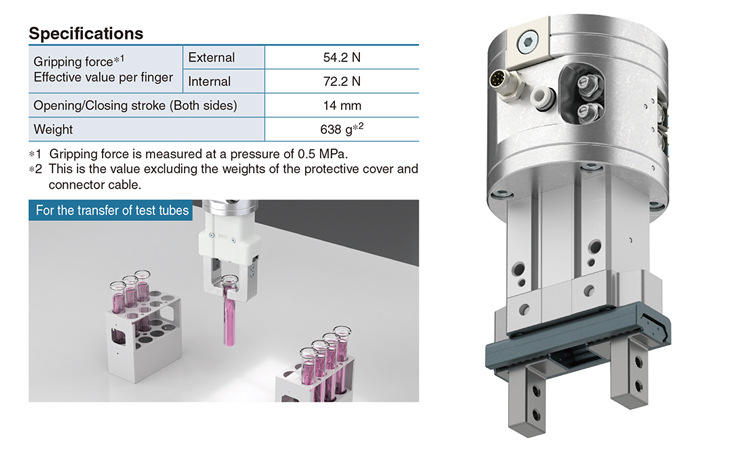

3-Finger Type RMHS3 Series

・Suitable for axial gripping of cylindrical workpieces

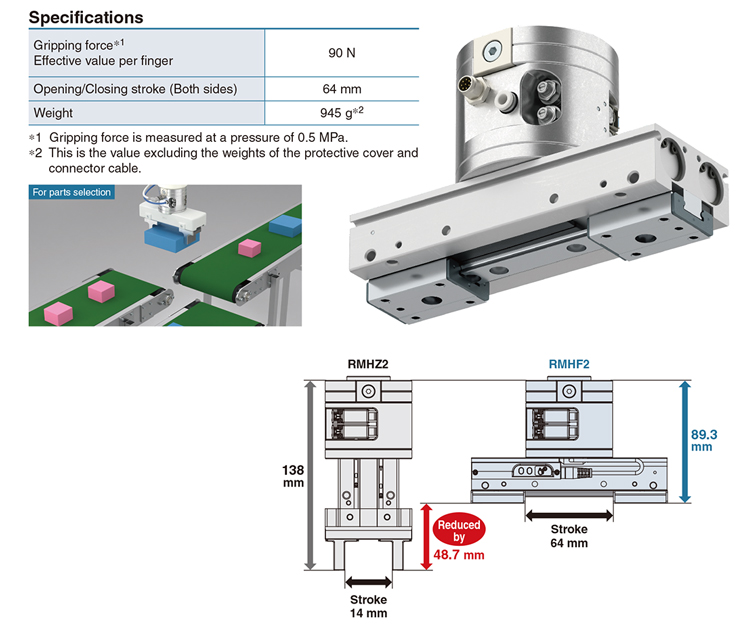

Long Stroke Type RMHF2 Series

・The 64 mm long stroke is ideal for a variety of workpieces.

・Height reduced by approx. 35% (Compared with the standard type)

・Actuator position sensor mountableLong Stroke Type RMHF2 Series

Operation is possible simply by connecting 1 air supply tube and 1 electrical wire.

・Integrated solenoid valve, speed adjustment mechanism, and auto switchOperation is possible simply by connecting 1 air supply tube and 1 electrical wire.

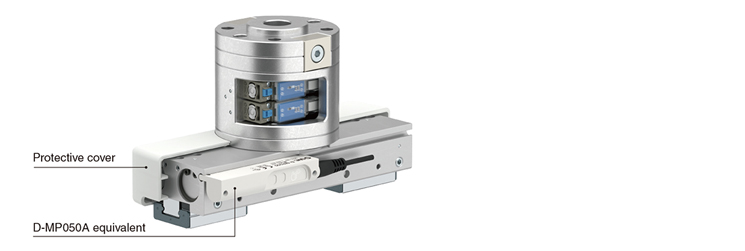

Easier mounting and maintenance

・A split protective cover for easy air gripper maintenance

・Standards: ISO 9409-1-50-4-M6Easier mounting and maintenance

Easy tool changing via the manual changer Reduced mounting and maintenance laborEasy tool changing via the manual changer Reduced mounting and maintenance labor

Air consumption reduced by up to 80%

・Air consumption is significantly reduced compared to when the solenoid valve is installed separately for the same type of model.Air consumption reduced by up to 80%

An actuator position sensor can be mounted on the RMHF2. (Option)

(Collaborative robot manufacturer: Compatible with robots from UNIVERSAL ROBOTS and FANUC CORPORATION)

Workpiece length measurement and discrimination can be performed.

・The stroke position is output with an analog signal.

・Repeatability: 0.1 mmAn actuator position sensor can be mounted on the RMHF2. (Option)

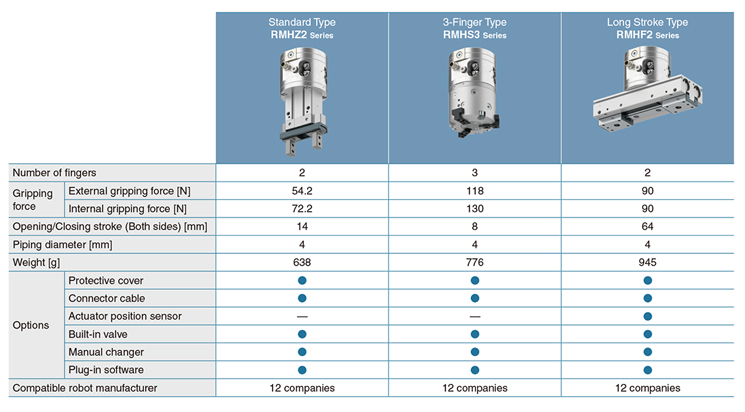

Series Variations

Options

Plug-in Software

Compatible with robots from UNIVERSAL ROBOTS, OMRON Corporation/TECHMAN ROBOT, FANUC CORPORATION, and YASKAWA Electric Corporation